Join the Fool for a chat with Dassault Systèmes Senior VP Al Bunshaft about how 3D design software contributes to innovation in fields from consumer goods to health care.

With 3D printers are on everyone's mind lately, it was important to chat with Dassault Systèmes, which provides the software behind this booming industry. Bunshaft explains the different segments of DS, its role in the 3D printing boom, and where it sees its future growth.

A full transcript follows the video.

Brendan Byrnes: Hi Fools, I'm Brendan Byrnes, and I'm joined today by Al Bunshaft. He is a senior VP at Dassault Systèmes. Thank you so much for your time today.

Al Bunshaft: My pleasure, thank you.

Byrnes: I was wondering if maybe you can give someone that's not familiar with Dassault Systèmes a quick overview of what you all do, exactly.

Bunshaft: Dassault Systèmes is a 31-year-old software company. We're made up of scientists, engineers, mathematicians. What we produce is software.

Our software is used to facilitate innovation in a wide range of industries, from aerospace and automotive to consumer goods, life sciences, construction; a wide range of industries.

Byrnes: I think it's really interesting, the amount of things that your software is used on, as you were saying. What are some companies, specifically that use it, and maybe some applications that they use it for?

Bunshaft: It's really a remarkable range of types of industries that are taking advantage of what we refer to as "3D Experience Technologies."

We make possible the ability to model a product physically and see it, and capture its description digitally, not only in the physical model, but then to be able to simulate and verify that product -- even manufacture it in the virtual world -- before anything is done in the real world.

Companies like Boeing, companies like Ford, companies like Procter & Gamble use our software.

Byrnes: How would Boeing, specifically, use it, or a Ford, if you could maybe pick one? How they would be helped out by this, exactly?

Bunshaft: I think a really, really cool example is right in our backyard here. The Barclays Center was designed by a company called SHoP Construction and SHoP Architects, and they use our software.

If you've seen the exterior of the Barclays Center, it's quite a dramatic curved, even sculptural shape made out of pre-weathered steel. What they did is they used our design software to achieve a cost point that was not possible through traditional methods. In fact, they tried to do it a traditional way, and they couldn't.

That exterior is made of 12,000 pieces of weathered steel. Not a single two pieces are the same, and through the software control of the entire end-to-end construction project, they were able to deliver that project on time and under cost.

Byrnes: Digging more into your two segments, you have two main segments which are PLM software, and then you have the SolidWorks software. Could you explain the difference between those two, and where you see the growth with those?

Bunshaft: Yes. We have actually 10 different brands, and we continue to grow. Most recently, we acquired a manufacturing company on the West Coast; just closed that transaction in July.

We have two families of software, as you described. One is our PLM software, primarily for the high end. Most sophisticated mechanical things in the world are designed with our PLM software.

Then what we call the mainstream 3D segment, SolidWorks -- a company we acquired over 10 years ago -- that now has over two million end users, so it's a very high-volume segment for everything from mom & pop shops that are designing small parts, all the way through the largest companies in the world as well.

Byrnes: I think a lot of investors are looking at this, and they see these 3D printing companies; 3D Systems and Stratasys have been on a tear recently. You guys have had a great run as well, but I think some mistakenly think that you're a 3D printing company, but you're not.

Could you talk about if maybe you guys are affected in any way by this "3D printing revolution," and how you guys look at that?

Bunshaft: We're absolutely affected by it, because our software is the engine of the 3D printing industry. People that are using 3D printing need to create their model data somewhere, and our software plays that role.

Whether it's SolidWorks or whether it's the high end with CATIA design software, many if not most of the models -- the parts, the objects -- that are being printed are designed on our software. In fact, the SHoP construction and architecture company for Barclays did print prototypes and models of their design using 3D printing as part of their process.

3D printing is truly transformative, in that it's making possible manufacturing at a scale it couldn't happen before, and it's making possible very rapid turnaround time for prototyping and production, that wasn't possible before.

Byrnes: Yeah, I think a lot of people are just hearing about 3D printing now, but as you said, it's been around for a while.

Bunshaft: It has.

Byrnes: Dassault Systèmes has been around for over 30 years, so why are people just hearing about it now? Has the technology gotten that much better recently, in the past five years, decade, or so? Or is it just becoming more and more ubiquitous out there, that people are seeing it more?

Bunshaft: Yeah, like so many advanced technologies -- in this case, advanced manufacturing technology -- the recent few years has seen a rapid acceleration in the cost point that 3D printers can be delivered at. That's one.

The second thing is the materials have advanced significantly, so you see companies like GE Aviation, even very small car companies that we work with, printing in metal.

With a combination of powders and lasers and the right materials, you can actually build up -- 3D printing is sometimes called "additive manufacturing" -- so layer by layer you can actually manufacture not only plastic parts, polymer parts, but now metal parts. Now you're into, really, the big time of manufacturing when you start working with advanced metals.

Byrnes: Yeah. You mentioned that technology is getting that much better. Is there anything you've seen recently, where you just thought, "How is that possible?" What's the coolest thing that you've seen recently, that you didn't think would be possible with 3D printing, or 3D software?

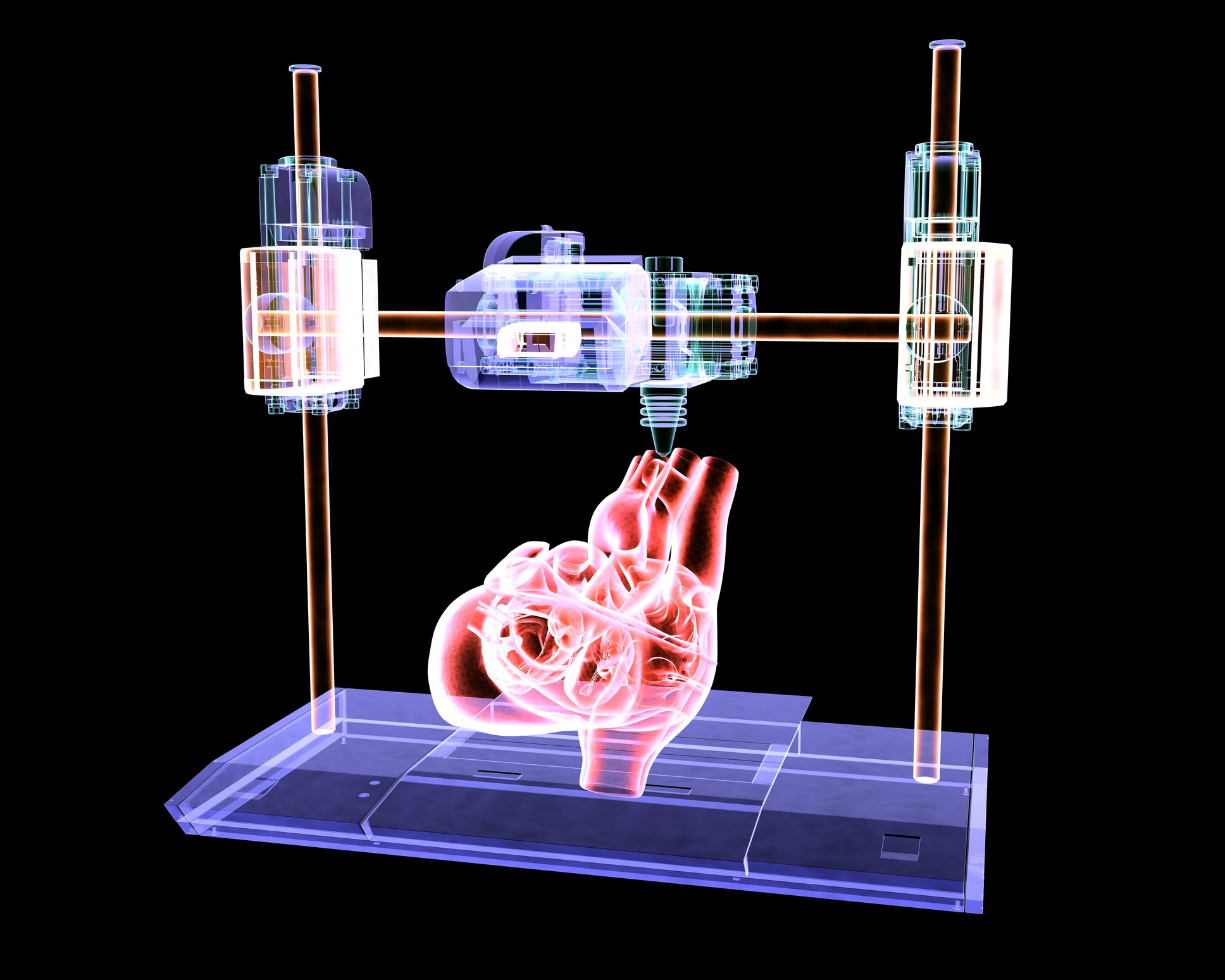

Bunshaft: Well, as an example, one thing that's happening is it's pervading many, many industries. A recent example we had was a medical collaboration that is printing not only models of hearts as a way to understand the surgery that has to be done and explain the procedure to the patient, but the model of the patient's heart.

It's an exact replica of, if you will, the environment the surgeon is going to go into, and a way to explain to the patient exactly where, possibly, the defect is or the implant's going to take place. Very, very instructive, in that case, in the medical industry.

Byrnes: You guys have quite a few competitors in the space, but you've also been doing very well recently -- companies like Autodesk -- what's your competitive advantage, where you can use your software in so many of these 3D printers where others maybe are not?

Bunshaft: First of all, I think we have the most breadth of any company in this space. We have 10 different brands, ranging from our mainstream 3D offering, SolidWorks, to our portfolio of products which form a platform that we refer to as the 3D Experience Platform.

We've been recognized as a strategic leader in this industry, and I believe we will continue to be, through this 3D Experience strategy that we're executing today.

We're focused on executing the expansion of our addressable market from a $16 billion PLM market that our analysts recognize today, to what we believe is a $32 billion addressable market, leveraging not only these advanced technologies such as 3D printing, such as digital manufacturing, but leveraging social media capabilities, because the way we collaborate and the way we work together as individuals and teams is changing dramatically.

We've made a number of moves to acquire technologies and develop technologies that provide new ways for innovators to collaborate.

Byrnes: Quite a bit of your revenue is recurring, is that correct?

Bunshaft: Yeah, over 70% of our revenue is recurring, and over the last 10 years I believe our revenue growth's been about 14% on average, so we've had a good, steady track record in that regard.

Byrnes: All right, well it's a very interesting company, helping print everything from things at Boeing with the Dreamliner, all the way to L'Oreal. Very fascinating company; investors, take a look at it if you haven't already.

Al Bunshaft, Senior VP at Dassault Systèmes. Thank you.

Bunshaft: Thank you very much.