The military once funded a little thing called ARPANET that went on to change the world. It might be about to change the world again with a bigger thing -- a 3-D printer that can lay down an entire house in just one day.

The project, dreamed up by engineering professor and 3-D printing expert Behrokh Khoshnevis, is partially funded by the Office of Naval Research and has been in development for roughly a decade. Several years ago, Caterpillar (CAT 1.36%) joined the effort by lending its engineering talent to Khoshnevis' team. By last fall, Khoshnevis' start-up, Contour Crafting, had used 3-D printing tools to build a six-foot-tall wall that could function as the exterior of a modern home. Its ultimate goal, of course, is more ambitious: a 2,500-square-foot house, laid down in 24 hours.

Source: Contour Crafting.

Contour Crafting's printing machinery is reportedly able to extrude concrete with a load rating of 10,000 pounds per square inch, a good deal higher than conventional concrete's 7,000 PSI load capabilities and no mean feat considering how difficult it can be to work with wet concrete. The construction printer might even be made to climb up the side of a multistory structure as it builds, story by story, with the help of a gantry frame -- the machine itself is said to weigh only 500 pounds. However, this doesn't mean that construction as we know it will become wholly obsolete -- digging the foundation, inserting structural supports, and installing doors, windows, and the other necessary "guts" of a modern home would still require human hands.

What 3-D printed construction does enable, however, is the rapid assembly of housing and other buildings in far-flung locations where traditional construction crews might not safely or efficiently work. Since the design of the final structure need only be constrained by the capabilities of building materials and by the fidelity of the 3-D printing constructor, the buildings need not resemble today's blocky homes at all, and more structurally sound buildings using curved geometry could be laid down with relative ease. This is of particular interest to the military, particularly after a decade spent fighting insurgents in some of the more remote and inhospitable parts of the world. The whole construction apparatus might be flown to the site, or even parachute-dropped, by one of the Air Force's many hefty C-17 transport aircraft.

Khoshnevis and Contour Crafting's long-run ambitions are as world-changing as those of many 3-D printing enthusiasts -- but while traditional 3-D printers fall somewhat short of transforming manufacturing, the 3-D printed house could spark a very real revolution in the global construction industry. Michael Molitch-Hou's feature on Contour Crafting, written last fall for the 3D Printing Industry blog, noted that 400,000 people are hurt and up to 10,000 are killed in construction accidents each year in the United States alone. Those numbers are bound to be much higher in the rest of the world, so reducing injuries and eliminating accidental deaths by sending 3-D printers to do the bigger and more dangerous jobs first would be a huge benefit to the industry.

Additionally, as the technology to 3-D print buildings becomes mainstream, it should also become efficient enough to provide low-cost housing in the developing world that's nearly on par with what we've become accustomed to in the developed one. Khoshnevis himself feels that modern construction techniques are highly wasteful and prone to corruption -- using only what's necessary via 3-D printed efficiency should raise up housing at a fraction of current costs around the world.

The fit and finish of those homes would certainly be highly customizable as well, with wealthier homebuyers enjoying a far plusher completed home than the bare-bones dwellings constructed for the poor. Smaller 3-D printers made by your favorite public companies could be great assistants in this customization process. 3D Systems (DDD +2.63%), for example, recently launched the CeraJet ceramic printer, a machine under $10,000 that offers the possibility of bespoke tiling, and rival Stratasys (SSYS 2.98%) plans to expand into metal printing, which could be used to create custom fixtures for these custom homes.

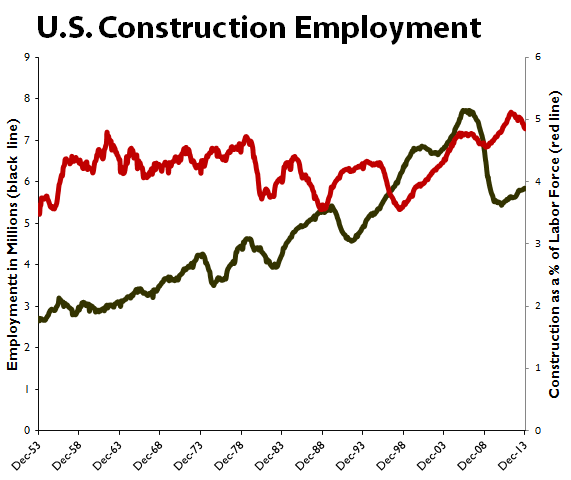

The downside to this new technology, as seems to be the case with the eventual 3-D cannibalization of traditional manufacturing, is that it puts millions of jobs at risk both here and abroad. The U.S construction industry has historically employed at least 4% of the labor force, and more often employs close to 5% -- that's a lot of labor to lose in an economy that's already finding it hard to provide new jobs for those put out of work by the Great Recession:

Source: St. Louis Federal Reserve (FRED).

The labor-force dislocation created by 3-D printing entire buildings might turn out to be worth the long-term benefit of better, cheaper housing for all, but it's still far too early to tell just what the impact of this technology might be. The Navy probably isn't thinking about these effects today, just as the military couldn't have foreseen the ways in which ARPANET would evolve into the Internet and change the way the whole world communicated. It's not too early to start, though. Will 3-D printed housing help end poverty as we know it by giving even the most destitute a place to call home, or will it throw so many construction workers off the job that it winds up making income inequality worse?