Companies that make 3-D printing machines that can print in titanium, which include 3D Systems Corp. (DDD +17.43%) and Arcam, could be big winners if a newly developed process that cuts the cost of titanium powder by up to 75% works as well as is being reported.

Cambridge University spin-off Metalysis developed the process and reportedly is in talks with commercial partners to build a $500 million plant to churn out low-cost titanium powder. Titanium is incredibly lightweight, yet also strong and highly corrosion resistant. These properties make it a top materials choice for aerospace applications, certain medical implants, and other specialty uses, yet its high price means it isn't employed much in mass manufacturing.

Of the five major 3-D printing companies that trade on U.S. exchanges, only industry leader 3D Systems Corp. and Sweden-based Arcam make systems with titanium and/or titanium alloy capabilities; ExOne has reportedly been working on developing this capability, while Stratasys and voxeljet don't offer any systems that can print in metals.

The 3-D printing titanium players

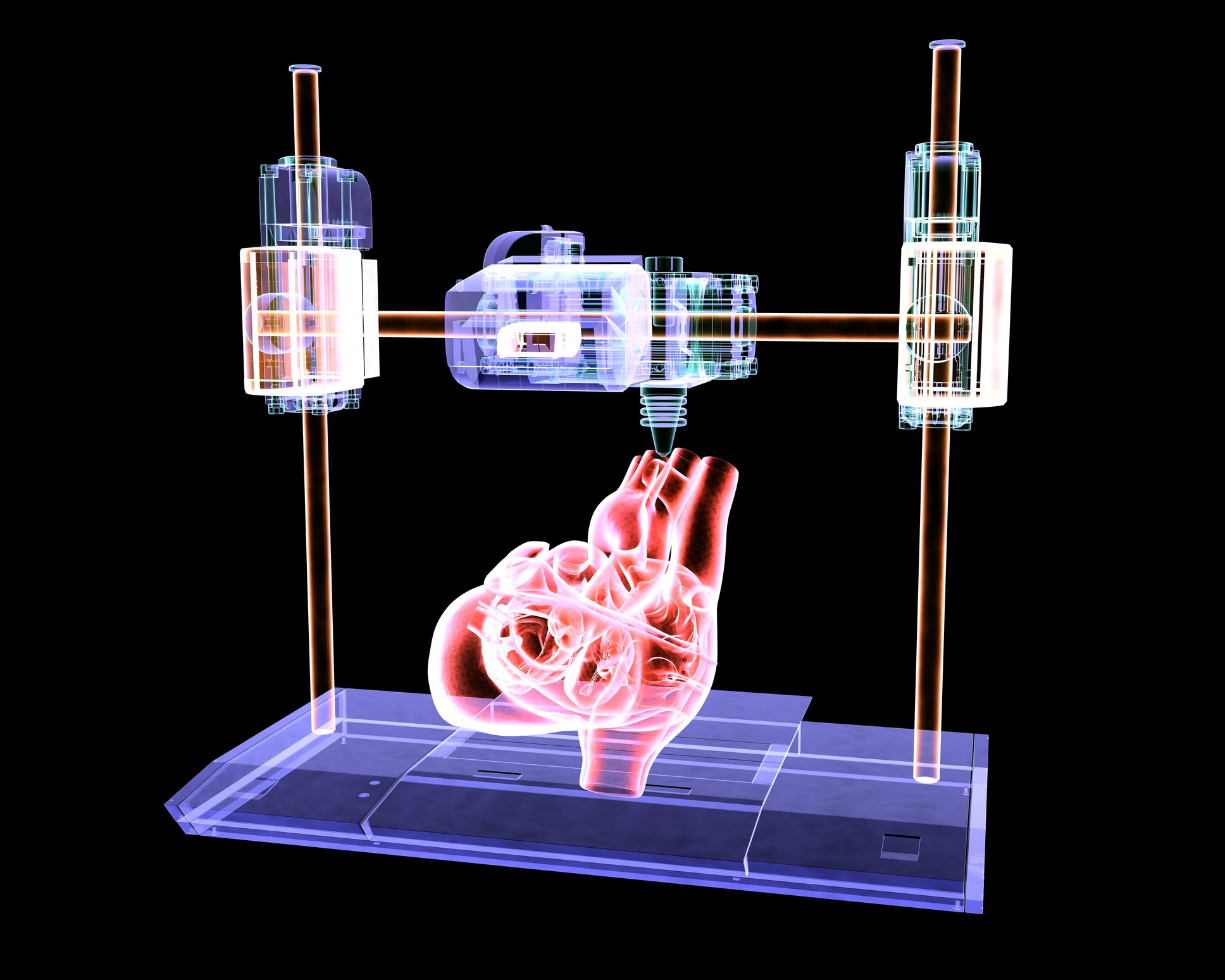

This development could turbocharge the already fast-growing 3-D printing sector because the lower-cost titanium will only be available in powder form: 3-D printing uses powder as a raw material, while conventional "subtractive" manufacturing uses solid materials.

It's very likely that some companies that now use other metals to produce certain components will consider using titanium if it's more competitively priced. Higher-end automakers and others will likely start using titanium for select parts that are now made from aluminum or steel.

The titanium powder produced by Metalysis' process is high-grade, but not quite aerospace-grade. So, at this point, manufacturers that currently produce titanium aerospace components using conventional manufacturing won't have the extra cost-savings incentive to switch to 3-D printing.

3D Systems Corp. only recently acquired metals printing capabilities when it bought Phenix Systems last summer. Its printers use laser sintering technology, which is the most commonly used metals 3-D printing technology. 3D Systems Corp.'s machines can print in stainless steel, tool steels, aluminum, titanium, precious metals, among other metals. There are a few privately held companies that also make 3-D printers that use laser sintering technology; most notable is Germany-based EOS.

3D Systems Corp. launched three rebranded Phenix Systems' printers at last year's EuroMold: ProX 100, ProX 200, and ProX 300, and is already competing for key new business with its new metal printer lineup. General Electric has reportedly been testing printers from 3D Systems Corp. to see if the company will be part of its capacity ramp-up necessary to produce thousands of fuel nozzles for its new Leap jet-engine.

Arcam has considerable experience making 3-D printers that have titanium capabilities, as it's been solely involved in the industrial metals end of the 3-D printing sector since it was founded in 1997 (though the company's roots and technology go back further). Arcam's 3-D printers use its proprietary electron beam melting, or EBM, technology, and can print in titanium, several titanium alloys, and a cobalt-chrome alloy. The company has been exclusively focused on two markets: aerospace and orthopedic implant.

Arcam's systems are relatively small, so they'd currently not be able to produce larger components in titanium. However, surely the company could develop and make larger systems using its EBM technology if demand warranted it.

Titanium economics, and titanium making 101

Metalysis' development could turn the metals markets topsy-turvy, as demand for titanium should rise at the expense of the aluminum and steel markets.

Titanium powder sold for $200 to $400 per kilogram, as of December. Shaving up to 75% off its cost would make titanium much more competitively priced with aluminum powders, which were selling for about $30-$50 per kilogram, and almost as cheap as specialty steels. Given the cost factor, it's not surprising only about 140,000 tons of titanium was produced and consumed globally in 2012, compared with 1.5 billion tons of steel and 48 million tons of aluminum, according to the Financial Times.

Titanium is now produced using the Knoll process, which is an 80-year-old technology that's very inefficient. The four-step process uses a lot of energy and only produces small quantities of titanium. By contrast, Metalysis' technology involves just one step. It uses electrolysis to convert rutile sand, a naturally occurring titanium ore present in beach sands, directly into powdered titanium.

This is here-and-now technology, not tech that's still in the R&D stage. Metalysis has long collaborated with SheffieldUniversity's MercuryCenter, which specializes in metal powder-based manufacturing. Engineers at the Center have successfully 3-D printed various components using titanium produced by Metalysis' process. This includes what they believe to be the world's first 3D-printed titanium car component, according to an article in TCT Magazine .

In what appears good news for Arcam, Prof. Iain Todd, director of the center, was quoted by TCT as saying: "We've been operating since 2007, which is when we got our first Arcam system. We're more focused around electron beams than lasers and we do a lot of work mainly with industrial partners, so our projects are supported by the European Regional Development Fund."

Foolish final thoughts

There are several reasons why investors might want to keep their eyes on Metalysis' progress in building a titanium powders production plant based on its technology. First, companies that make 3-D printers that can print in titanium, which include Arcam and 3D Systems Corporation, would almost surely see demand for their systems increase. Second, there could be some significant investment opportunities in the metals market. Lastly, Metalysis could make for a potentially attractive IPO.