In the following video, 3-D printing specialist Steve Heller interviews Jared Helfrich, global director at ExOne (XONE +0.00%).

Topics covered include:

- An overview of ExOne's strategy

- How ExOne's binder jetting technology is differentiated from the competition

- How superalloy Inconel 625 validates ExOne's technology for aerospace and expands its addressable market

- ExOne's biggest market opportunity in the next five years

A full transcript follows the video.

Steve Heller: Hey Fools, Steve Heller here. I'm joined today with Jared Helfrich of ExOne. He's a global director. Thank you for being here Jared we really appreciate your time.

Jared Helfrich: Thank you.

Steve: We're big fans of your company, we wanted to learn more about it. If you could tell us about the strategy, grand vision of ExOne, five years from now you guys are obviously an emerging growth company today, where do you see yourselves, what is your goal in the 3-D printing market space?

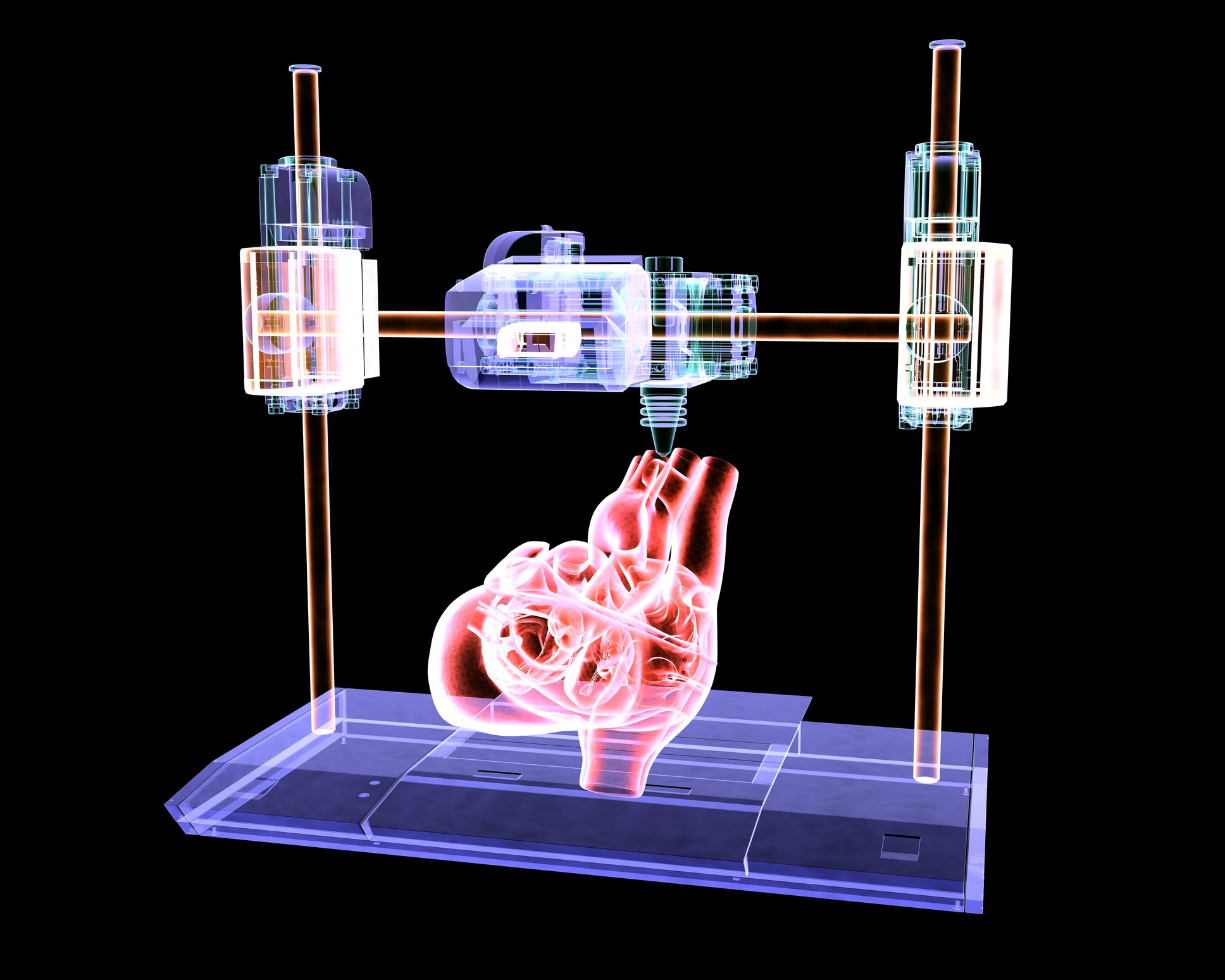

Jared: Yeah, our goal is basically, as you know, we have the binder jetting technology. We have two lines of business, we have a direct and indirect so for the indirect side we're basically looking to go more downstream for the casting business so it's more of the sand mold, sand cores and also came out with machines that you would see in short-term series production; so basically faster paced machines that you see in short-run series production.

For direct printing it's all about getting out new materials. Seeing our materials get more into the hands of people, greater install base and growing that business with materials that are coming out and growing the install base for director printer.

Steve: Very good, so in terms of your sand casting, so a company like Ford, for example, they can 3-D print an actual functioning engine without using any tooling required they just 3-D print a sand mold and they pour their aluminum in there and they make a functioning engine?

Jared: Correct. It's basically as it is right now is adding less cores is how we basically say it.

Steve: Okay.

Jared: So you print in our S-Max or in our S-Print, it's about a 24-hour build box run and it's a patternless core, so it's a rapid prototype.

Steve: So there are huge cost advantages associated with that because there's no more tooling, there's no more sending it off waiting for the tool to be created so you guys probably increased lead time significantly?

Jared: There's lead time advantages and there's also, in short run production runs, there's definitely cost savings as well.

Steve: Very good.

Jared: Save on tooling and improve the lead time.

Steve: So in terms of ExOne's positioning in the marketplace you guys work with binder jetting technology, you're the only company out there with binder jetting technology is that correct?

Jared: Yes.

Steve: So that's obviously a differentiator so if you could explain to our viewers here, what does binder jetting technology -- how does it differentiate itself from the DMLS or direct metal laser sintering? You know, everyone at this conference seems to be touting DMLS so I was wondering if you can sort of talk about the advantages of binder jetting and what makes ExOne unique as a result of that?

Jared: Yeah, binder jetting is basically a process where you're laying down powdered metal or powdered sand and you're coming over with a print head and laying down the binder on top and building your part up layer by layer. The advantages are in terms of volume metric output you get higher volume metric output from the machines. In terms of build speed you're going to see higher build speeds as a result of that. Actually, the powdered bed in and of itself is its own support structure so you won't see support structures in our process.

Steve: So there's less post-processing?

Jared: There is post-processing in our machines but it's usually -- for sand there's no post-processing, for the metal there is a sintering process.

Steve: Right, you guys are putting it into a furnace to actually harden the part, is that correct?

Jared: Correct, correct.

Steve: Okay. So in terms of the applications around ExOne's technology, what would you say is your ideal customer?

Jared: Yeah, ideal customers are any OEM. Basically anybody in the industrial space?

Steve: Anybody that's casting metal, anybody that's working with heavy machinery, that's your target market?

Jared: Yeah, absolutely. It could be tooling, it could be general industry, it could be automotive, it could be aerospace; there's a variety of industrial applications.

Steve: Yeah, there's a lot of talk about aerospace these days and you guys just recently introduced this new metal, Inconel 625, is that sort of 3-D printed part, right?

Jared: Yes, it's a 3-D printed part of Inconel 625.

Steve: And this has 99% density or over 99?

Jared: Over 99, it's about 99.6% density.

Steve: So this essentially validates your technology to prove to the manufacturers that need that solid part component for really robust applications like jet engine components, things like that. Would binder jetting be a good fit for that now?

Jared: Yes. I mean, I think with binder jetting with the Inconel 625 it is a 99.7% dense, there's no matrix, there's no infiltrant, it's basically printed and it's sintered and this is the part, and hipped, that you can see.

Steve: Very good so the implications long-term is that you're -- ExOne, it seems to be coming more competitive in the direct metal 3-D printing space, everybody -- you know, direct metal laser sintering particularly, 99% density. This is a very popular hurdle to achieve so now is binder jetting well suited for aerospace? Can it handle as complicated a structure compared to direct metal laser sintering, is it as accurate, is it -- sort of what are the nuances between direct metal laser sintering and binder jetting technology?

Jared: I mean, certainly there's some differences. I mean, basically the binder jetting process you have faster speeds but you might not see the surface finish. There might be some differences in surface finish. This surface finish, as you see here is pretty good.

Steve: Yeah, it's very smooth honestly.

Jared: So in terms of the differences I'd say maybe see some differences in surface finish and tolerances but I think -- I would say that those are probably the big differences.

Steve: All right, very good. So in terms of your biggest opportunity, you're thinking out five years, your companies in a great position, your biggest opportunity now, you know, you guys recently had a strategy shift change instead of trying to target metal foundries you're finding that foundries don't necessarily -- they're not as receptive to your technology, it kind of gives away their trade secret and all the magic so you're going direct to foundries customers now so there's that foundry side of the business and there's also the metal, direct metal, 3-D printing side. What would you say is like the biggest opportunity over the next five years?

Jared: Yeah, I think the big thing for us is to involve, we're looking to involve, both strategies. I mean, if there's a higher growth rate I'd say it's probably in the direct side but that doesn't mean in terms of core focus both of them are in our core focus.

Steve: Very good.

Jared: But in terms of where we want to see higher growth and higher growth rates we'd hope it's on the direct side.

Steve: All right, very good. Thank you so much Jared.

Jared: Okay, thank you.