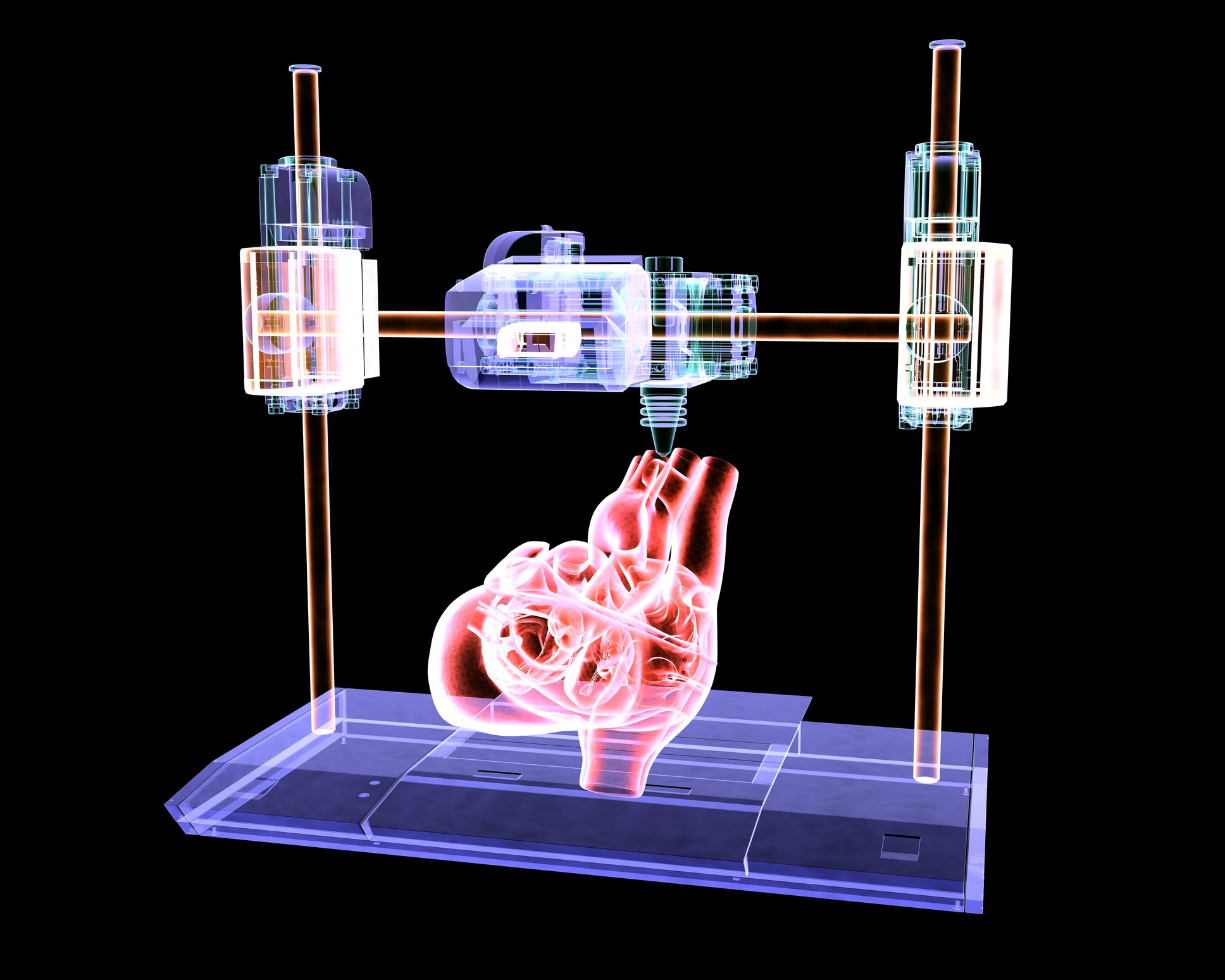

Source: ExOne.

Last week, industrial 3D printing specialist ExOne (XONE +0.00%) released its fourth-quarter and full-year earnings that came in below Wall Street expectations. Along with the release, management hosted a conference call so that investors could gain further insights into how ExOne is progressing toward its longer term goal of becoming a larger player in the 3D printing industry. Below are five key takeaways from the call.

1. ExOne has a "dominating" 3D printing technology in what it believes to be a multi-billion dollar market opportunity.

ExOne's binder jetting technology is best suited for industrial-focused applications that demand a high volume of parts and larger dimension parts. According to CEO Kent Rockwell, binder jetting appears to put ExOne in a great position to tap into what he believes to be a potentially massive market opportunity:

"... we have a dominating [binder jetting] technology in what appears to be multi-billion dollar market opportunity. And second to having that dominating technology, we have a very unique competitive position within that technology, inasmuch as right now, we are the leader in the binder jetting development, and I believe we have a very, very strong leadership position. And finally, we have a well-defined strategy for seizing the opportunities in this marketplace, and for moving on into the marketplace and succeeding to become a dominant player in that market."

2. ExOne has installed more than 200 of its 3D printers worldwide with customers.

A great way to measure a 3D printing technology's acceptance in the industry is to examine the number of 3D printers a company has "installed" with customers. The added benefit of having an installed base is the recurring revenue-generating potential it offers the underlying company as its printers are put to use and consume materials, which typically carry a high margin.

During the conference call, Rockwell highlighted that ExOne has installed more than 200 of its 3D printers worldwide, and systems from 10 years ago are still running strong:

"Our binder jetting technology has a globally installed base now of more than 200 units running around the globe and we're feeling that most of them are running in pretty good shape. We haven't had very many units that are actually retired even over the eight years, nine years, 10 years that some of them have been in place."

In terms of furthering the acceptance of binder jetting, Rockwell believes it comes down to lowering costs:

"So it's all about just driving down cost to get a wider acceptance. And in the industrial customers, they're tough to move up or down [on price]. They really want to see that it works [in a cost-effective way]. And so they've gone from being suspicious to now being pleased enough that they're ready to look at program installations."

A metal 3D-printed part. Souce: ExOne.

3. Binder jetting is starting to compete on price against some traditional manufacturing processes.

In order for a large-scale industrial manufacturer to change its processes and adopt ExOne's 3D printing tech, there has to be a compelling reason to do so. Making an economic change certainly helps that cause.

Fortunately, Rockwell's team has been focused on driving down the operating costs of ExOne's printer, to the point that they're becoming cost competitive against some traditional manufacturing processes:

"... as we start to move from prototyping to production because we're starting to drive costs down to where we are now competitive with traditional processes such as blow-mold lines and other shop processes on a cost basis to be able to get our customers to move to this new technology and the benefits that it brings."

Looking ahead, if ExOne can continue driving down its printers' operating costs to the point that it's almost a no-brainer for industrial manufacturers to adopt them over traditional manufacturing processes, it could have a major impact on adoption rates.

4. Machines sales were down year over year because two-thirds of ExOne's revenue is tied to global economic activity.

On a full-year basis, ExOne's machines sales were down about 8.5%, which could suggest that the company is struggling to grow acceptance of its binder jetting technology. However, Rockwell explained that ExOne is a global company that can be subjected to economic headwinds:

"And so two-thirds of our business is still coming from outside the U.S. That leads to why machine demand was down a little bit. The European economy was very, very soft in capital spending last year and it's starting to pick up again now.

Similarly, we had the experience in Japan where the Japanese government sort of imposed a sanction against buying ExOne machines while they tried to develop a government program for these machines, which has now been abandoned, and they're back buying our machines again. But for three quarters, we didn't have any activity in Japan."

In other words, economic uncertainty in a geographic region can affect ExOne's operating performance, but isn't necessarily indicative of demand.

5. Management doesn't think its S-Max printer will be cannibalized from its upcoming Exerial system.

ExOne recently announced a new 3D printing system called Exerial that bridges the gap between small-batch 3D printing manufacturing and larger-scale production needs, which it expects will be available by early 2016. The Exerial 3D printing production platform boasts two build boxes that are each 1.5-times larger than its S-Max 3D printer, currently the largest format 3D printer in its portfolio.

ExOne's Exerial beta system. Source: ExOne.

During the Q&A session, an analyst asked whether Exerial threatens to cannibalize the company's existing S-Max printer line. Rockwell admitted that they were unsure, but thought that they'll be enough of a differentiation in terms of price and features that will keep the product lines from blurring:

"Everybody is wondering that, including ourselves [if Exerial will cannibalize S-Max]. But in my own opinion, there are two different markets [that S-Max and Exerial cater to] and there's two different opportunities. The output of the Exerial is so much larger than what some individuals would require an output, and also the applications for them are particular to some high-volume interests, such as in automotive production that wouldn't be applicable [to S-Max] where you're doing 400, 500 of pump impellers and then some castings and everything. So I think it's different – they're different customers."

Putting it all together

Although ExOne has struggled to meet Wall Street expectations since becoming a public company, the 3D printing specialist continues to take action toward becoming an increasingly relevant player in the industrial 3D printing sector. Consequently, the current disconnect between the stock price and the actions taken by management could prove to be a great buying opportunity for long-term investors as long as management can successfully deliver on its vision.