Although speed, running cost, and materials are commonly cited as areas the 3D printing industry needs to improve before it can grow to represent a greater presence in manufacturing, the highly critical marriage between software and hardware is often overlooked. From an operator perspective, without bridging software and hardware to work more fluidly together, it could be difficult to realize technological advancements on the hardware side of 3D printing.

During the Inside 3D Printing Conference held in New York City last month, 3D printing specialist Steve Heller had the opportunity to interview Mcor Technologies CEO Conor MacCormack about the challenges facing 3D printing adoption rates over the next five years. Mcor Technologies manufactures 3D printers that use ordinary copy paper to produce monochrome and full-color 3D-printed objects for a fraction of its competitors' operating cost.

During the discussion, it came to light that there's an apparent talent gap in the 3D printing industry to find software programmers with the proper experience to interface with 3D printing hardware. The following video highlights the conversation, and a full transcript is below.

Steve Heller: With every strength there's probably a little bit of weakness, maybe a challenge to overcome with 3D printing. What do you see as some of the greatest challenges affecting 3D printing adoption rates over the next five years?

Conor MacCormack: One of the big problems that we were always worried about was the hype. People were saying, "I'm going to get a printer and I'm going to print a mobile phone. I'm going to print something that's going to go into a car," or something like that.

The reality is that, A, the technologies maybe right now aren't at that point, and B, people have no inclination to open up the bonnet of the car and take a piece of the carburetor out and put a new one in. People want to get into the car and hit the ignition and drive. There's only a very small group of people that ever wanted to do that kind of thing.

For us, we're glad that the hype has cooled down, but as we see here at the show, the buzz is still the same. The growth in the companies is still growing. Stratasys and 3D Systems are still growing at 20-30%, on average in between there, and [Mcor is] seeing even bigger growth than that.

Every quarter, 3D printing companies are still making more and more massive growth strides, and I think that the market will start to look at that.

But some of the challenges that we see -- when you talk about all the opportunities and the strengths, it can be a challenge if you want to print something that's really, really complex, and what kind of object you can get out of the printers.

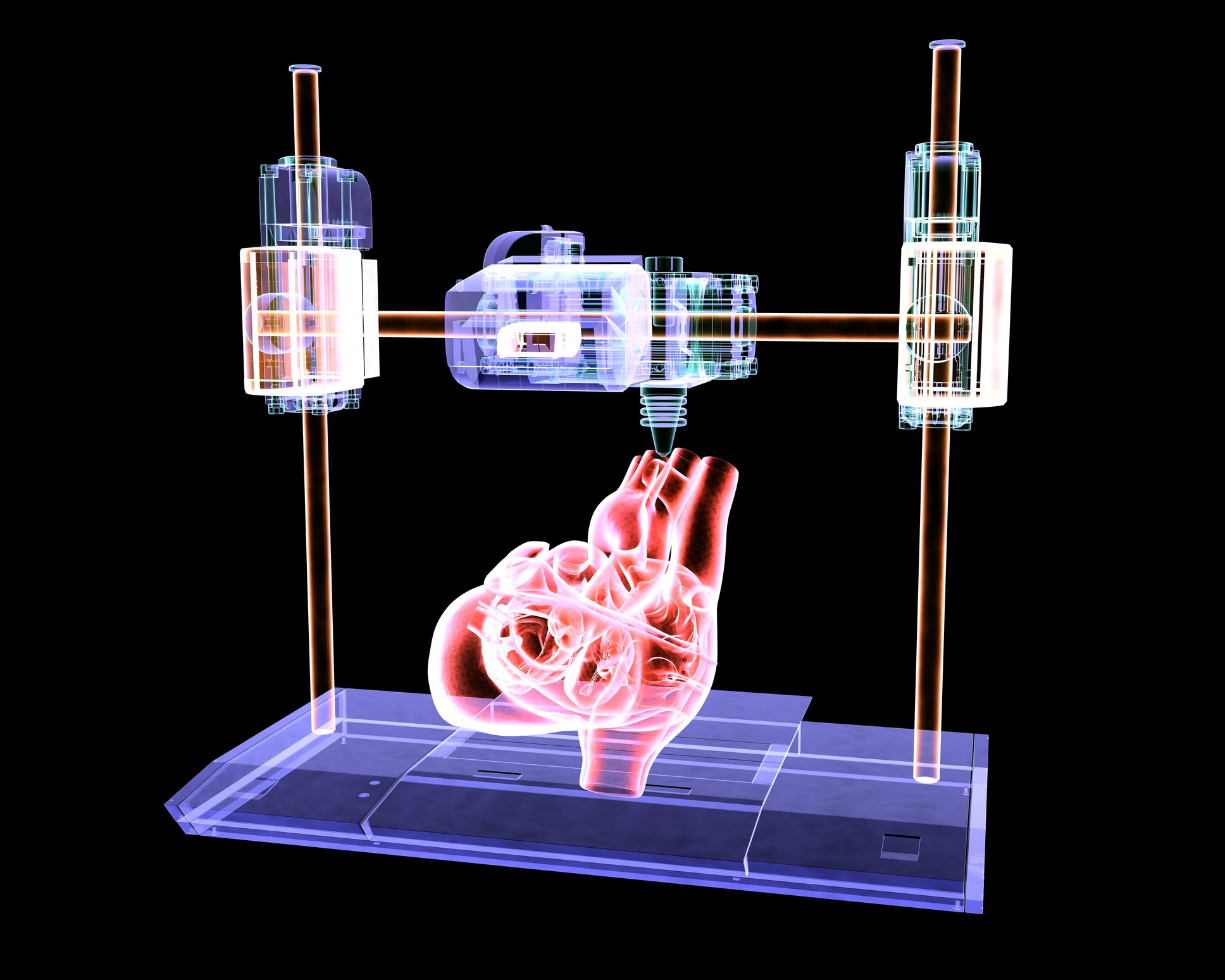

People still say, "I want to print conductive layers," "I want to print electronics," "I want to print bioengineering parts."

Speed is also always a challenge. There are new printers that are coming out, like the Carbon3D printer that's claiming to print 100 times faster than other technologies, and that's fantastic. But it's not just speed. It's use cases, it's applications, it's the cost of the consumables, it's the environmentally friendly footprint of the parts you're producing.

There are lots of different challenges that are right there, but I do believe that they're all being solved in different ways. I think we will look back at this time and say it was a change.

People use "Industrial Revolution." Maybe a bit too much. I think the industrial machines are going to be more a complementary product to the machining machines that are out there.

If you look back at the classic Industrial Revolution, it [occurred] when something was manual that changed to automation. That was the big Industrial Revolution. You can't really say the same thing about machinery that's around now in engineering.

You have CNC machines, milling machines, all these very complex molding techniques. 3D printing is going to be complementary to that [subset of manufacturing]. Some of them it will replace, but it's not going to replace them all.

I see maybe some opportunities in education. I think that there's real opportunity for maybe even, dare I say it, an educational revolution. There's no hardware in the classroom now. You have a teacher standing in front of the students, in front of a whiteboard or a chalkboard. It's been like that for hundreds of years. There's an opportunity there to get hardware in there, and I think there's a real opportunity to really make a big difference in education.

Heller: In thinking of other challenges here, there's a little bit of a talent shortage across the industry, where maybe it's hard to find talent.

Are you experiencing anything like that at Mcor, where you're having trouble filling positions, that you're looking for new engineers or someone that actually has a really solid understanding in actually how to use the technology in real-world applications?

MacCormack: Yes. One of the areas that we've always had difficulty with -- and we're very lucky in Ireland that all of our R&D is done out of Ireland and we have a very good educational system there. But one of the challenges we have found is software integration to hardware.

Programmers go to college and they learn Java and they learn all of these various packages, but when you interview them, you get them in, it's Java to do a website. But if you want to say, "I want you to write a piece of software to interact with a piece of hardware," then it's like that piece hasn't been taught at the very highest level.

That's changing now at a lower level, and I think the likes of 3D printers are making that happen; the way you can have a breadboard or you can have an Arduino, or you can have 3D-printed objects and you write a bit of code, and the kids can do it.

CoderDojo, I don't know if you're familiar with that. It's a very big movement that's going around the world where kids can -- like a black belt, like a dojo and black belt -- but you're coding.

Universities will offer their time for free. Guys will get the local kids in the area and they'll turn up like once every month, and they're taught how to code using Scratch, the MIT software where it's all object-oriented and it's very easy to stick modules together and actually have a physical output. You could have a fan turning.

I think that's really going to help, and a couple years down the line you're going to have a very big integration between software and controlling things in the hardware. But at the moment, that's one of the areas where we find difficulty. But we're trying to fill that gap as best we can.