In the following video, 3D printing specialist Steve Heller interviews Conor MacCormack, CEO of Mcor Technologies, at EuroMold 2014, the world's largest 3D printing conference held in Frankfurt, Germany, in November. Headquartered in Dunleer, Ireland, Mcor offers 3D printers that utilize ordinary copy paper as the primary feedstock, significantly reducing operating costs compared to the competition's razor-and-blade approach. The other major advantage is the photo-realistic results it can create:

This paper T-rex was 3D-printed on Mcor's full-color 3D printer. Source: Mcor Technologies.

During the segment, MacCormack explains why Mcor is attending the industrial-focused EuroMold 3D printing conference, and the value proposition behind using ordinary paper as its primary feedstock.

A full transcript follows the video.

Steve Heller: Steve Heller, here. I'm joined today with Conor MacCormack, CEO of Mcor Technologies.

Mcor is a very interesting up-and-coming company in the additive manufacturing, 3D printing space. Their feedstock, or the primary material they use, is ordinary copy paper, and they're able to print -- as you can see behind me -- full-color designs using an inkjet-based technology. The operating costs are significantly lower. We'll get into that a little bit later.

Conor, I just want to talk to you a little bit about what you think about this year's turnout, at EuroMold 2014? What's the most surprising thing you've seen this year, and your take on the whole conference?

Conor MacCormack: How are you doing, Steve? It's good to see you again.

Yes, the show has been brilliant this year. Obviously, EuroMold is very much an industrial show. The different shows have different flavors. Some are consumer-oriented, but this one is very much talking to industry.

Some people initially think, "How is your technology suitable to that kind of industrial sector?" but the technology is so small -- the level of penetration -- that there's always applications that people haven't thought of. A lot of times with people coming over, it can be used for castings, investment castings; real-use, hard applications.

It's very important for us to be here. It's for getting the brand, it's for getting people to know about what we're doing, and then getting an opportunity for people to see the latest developments in the software, the new coatings that we have, the new algorithms that we've released to make that color really, really crisp and to get really super-high color quality in our material.

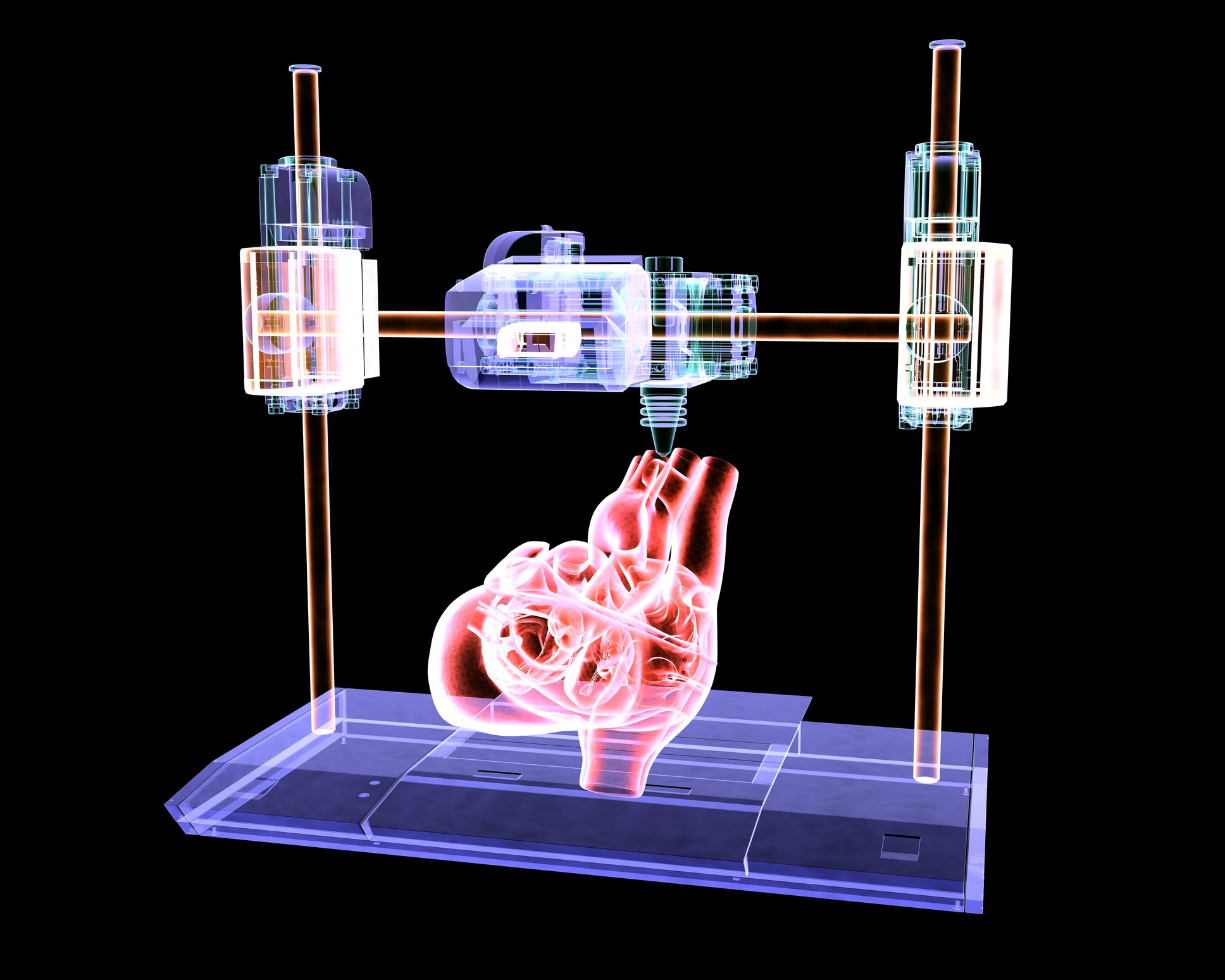

We've talked about this before, but our whole DNA of the company, our goal is to make a photo-realistic 3D-printed object. Because we use paper as the raw material, we believe that we're very well placed to make that happen. That's why we're very excited to be here at the show.

Heller: Talk me through the value proposition of using ordinary copy paper as your raw material. What makes your product so much more valuable than the competitive landscape, which usually uses thermoplastic and other more expensive materials?

MacCormack: I think... [banging noise in background] Sorry about that. That's actually a [paper] hammer that somebody has printed on our machine, hammering on the table. I don't know if that will make the video!

Heller: It might!

MacCormack: Effectively, the industry is really evolving. Before, people were trying to sell a machine to do everything. They were saying, "This machine can do from jewelry all the way to whatever different applications." But what is happening is that the market is maturing, and people are realizing that you really do sometimes need more than one machine.

The value proposition for us is that if you want to make a very low-cost part that's very high-quality, and if you want to have color on that, that is the real value proposition we're talking about.

Because we use paper and ink, our color is measurably higher color capability than anybody else. We have measurably the highest color capability in the 3D printing industry, so that's the first thing.

The second, because it uses paper and a water-based adhesive, the running costs on our machine are extremely low. You can be talking up to 20 times cheaper if it's a non-color part, like a white part or multicolor paper part. If you're using a full-color part, around maybe five times, 5x cheaper. That's the real value proposition.

It's a real business case. If you buy our machine, you can make high quality color parts at a fifth of the price of anything else. It's a simple thing, a simple mathematical formula. You can make money using our machine, and that's the value proposition.