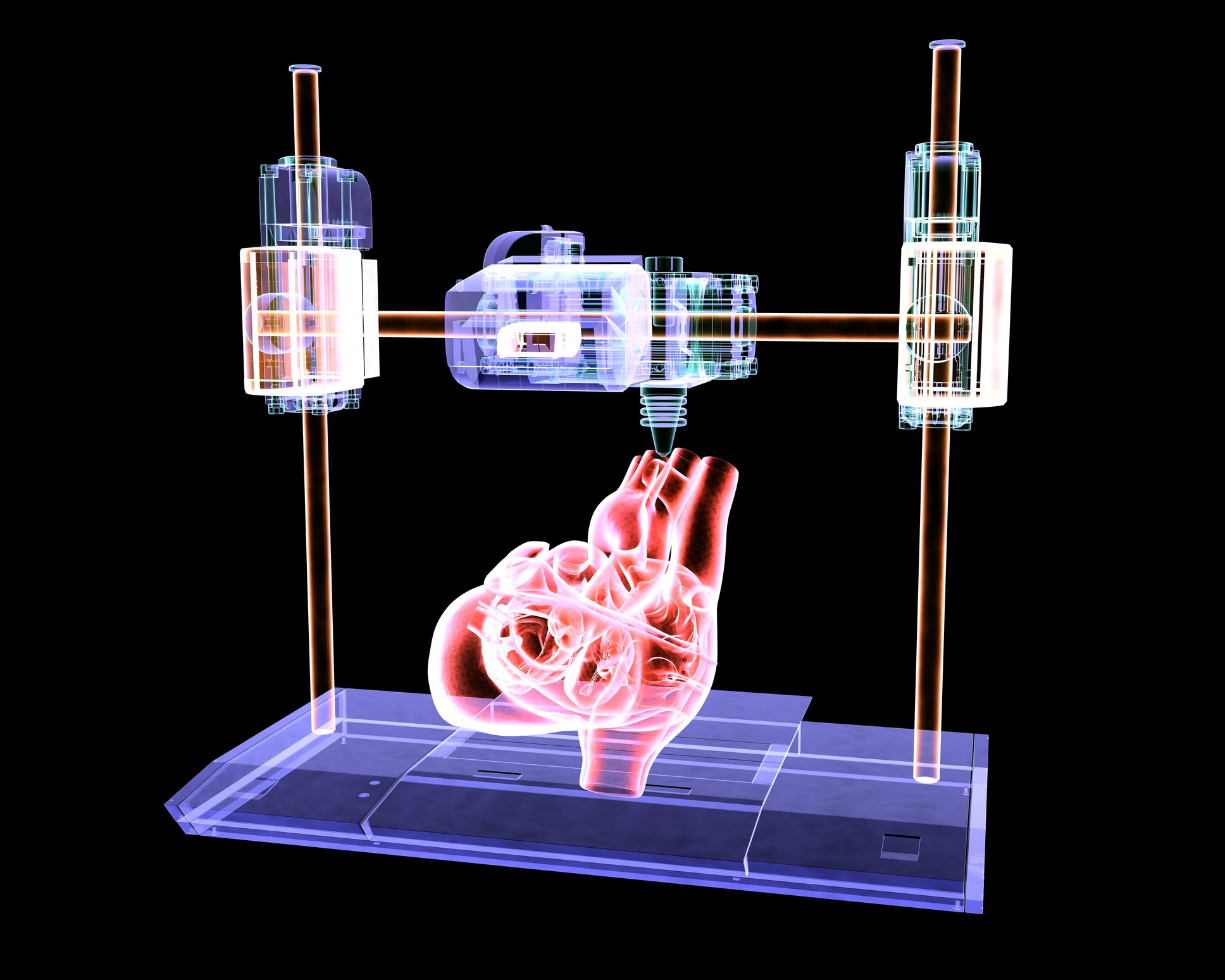

Over the last several years, the hype around 3D printing has been focused on how the technology is capable of revolutionizing manufacturing by offering the potential to fundamentally change the way things are made.

In some ways, that's a true statement, because 3D printing is an additive manufacturing process that builds objects one layer at a time. This process doesn't require tooling, and therefore invites higher levels of complexity than subtractive manufacturing, which cuts, mills, or drills an object into its final shape. Theoretically, 3D-printed parts and products have the potential to be fundamentally superior to their subtractive manufactured counterparts.

However, as a blanket statement, it's misleading to say that 3D printing will disrupt the entirety of manufacturing. Realistically, there are numerous manufacturing applications where the economics aren't likely to support 3D printing in terms of speed, cost, or practicality over conventional manufacturing techniques.

In the following video, 3D printing specialist Steve Heller interviews Rich Stump, principal at FATHOM, a boutique 3D printing service provider and rapid manufacturer, about the market opportunity that he expects out of the industry in the future.

During the segment, Stump touches on how he views the 3D printing industry in relation to the overall manufacturing industry, if prospective customers have the correct understanding of the technology's capabilities, and how FATHOM can compete against 3D printing majors 3D Systems and Stratasys.

A full transcript follows the video.

Steve Heller: This customer base that you're trying to tap into; being a boutique 3D printing consultative rapid manufacturer -- that's a mouthful! -- how do you put this opportunity into context? How big is this opportunity, in your mind?

Rich Stump: We're continuing to grow. The growth that we're seeing is significant. We are a smaller company, getting into the medium-size realm. I think as we look at, what does this opportunity bring for additive manufacturing/3D printing -- I like to say "innovative applications" -- is I think over the next 10 years or so we're going to see it be significant.

I don't like to paint the picture that 3D printing is going to change the way that all products are manufactured or designed. I like to paint the picture that 3D printing and additive manufacturing will have a significant impact on how we develop and design products in the future.

We're going to continue to use traditional technologies like CNC machining, injection molding, and other traditional manufacturing technologies, but we're going to have this hybrid approach where the additive and 3D printing side can play a role to do something big, and to change the way that customer is developing a product, that can make a significant impact to how that product performs.

In my opinion, Steve, I think that it's going to have a large impact over the next 10 years on this whole hybrid approach.

Heller: Are you seeing that a lot of your customers aren't necessarily that familiar with 3D printing, or it's pretty well-known at this point, the awareness?

Stump: The awareness, it's pretty well-known but sometimes falsely known. The whole Maker movement and the lower, consumer-level machines have done a great job at educating customers on the actual term "3D printing" -- but not done justice to what value the technology can bring to the customer.

I think from a technology perspective, customers understand it but need a lot of education on downstream [finished product] manufacturing. More innovative, advanced applications require a lot of education and hand-holding.

Heller: In terms of remaining differentiated, being a boutique services firm here in the rapid manufacturing and 3D printing space, there's been a lot of emphasis on M&A activity from 3D printing majors. Stratasys had some acquisitions, so has 3D Systems, just to bolster their service approach and act as a portal to sell some of their products. How does a boutique firm like yourself differentiate itself from a 3D printing major?

Stump: I think what's really different about our business are our assets of engineering design and other really good technologists that we have at FATHOM, that can engage with these clients and really help them take advantage of these technologies.

We try to optimize our processes internally, whether we're making parts or doing urethane castings or machining or molding -- whatever services we're providing -- which are competitive to some of the names that you've mentioned, so we do compete with them.

But where our customers come to us and say, "Hey, we have this problem. We don't know how to solve it. You need to engage with us and tell us what technologies to use," that's really our differentiator.

We're not just getting CAD [3D model] files and making parts and shipping out the parts. We're integrated to the customer's process to help them change their design or consult with them on different processes to use to achieve their goal for the project, or how they're developing that product in the future.