Although the exact contents of Coke’s syrup are a closely guarded secret, it’s known that some other confirmed ingredients are most commonly produced overseas, including caramel coloring (France), caffeine (China and South America), and phosphoric acid (mostly China).

The syrup is far from the only ingredient, though. Once the syrup is produced, it’s sold to a bottling partner or a Coca-Cola in-house division responsible for sales in North America and Canada. The syrup is mixed with ingredients that include filtered water and sweeteners. The bottling partner packages the beverages and distributes them to retailers.

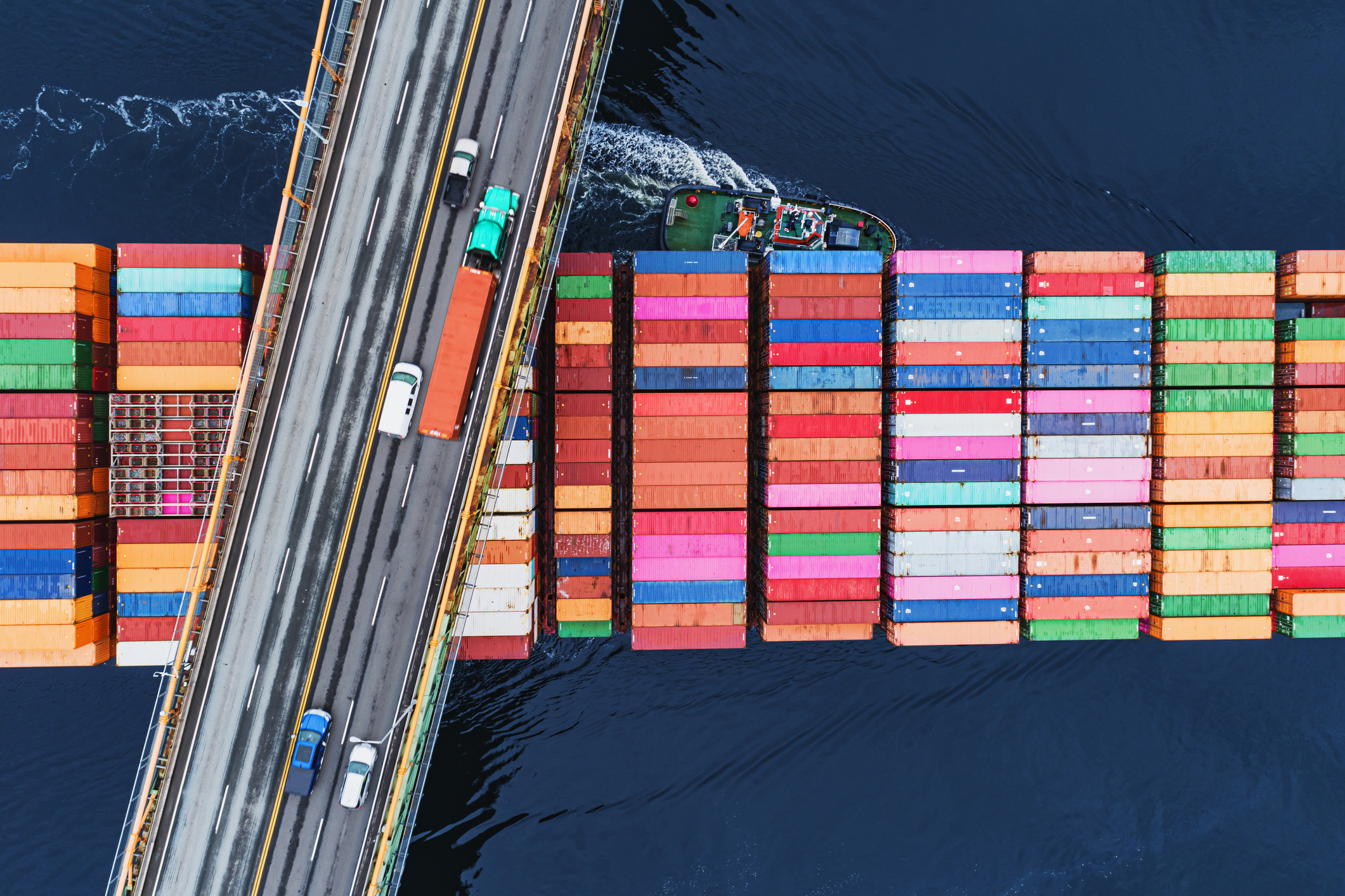

While the production and sale of a bottle of Coca-Cola may seem mundane, imagine all the things that could affect the company’s supply chain: A drought or natural disaster that affects the supply of corn, a labor strike in Europe, an excessively rainy or dry growing season for coffee fields in South America or Asia, or trade disputes with China.

At its best, a supply chain is a delicate ballet of dozens or more companies producing, manufacturing, and distributing materials that put an ample supply of goods on a store shelf.